Our website uses cookies, including third parties’ profiling cookies, to improve your user experience. You can learn more about how we use cookies and how to change your cookies settings in our Privacy Policy. By closing this message, clicking above or continuing to use this site, you consent to our use of cookies.

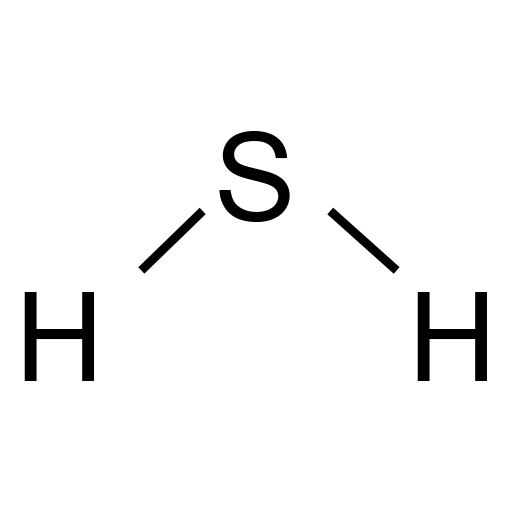

Biogas is a renewable energy source that is produced by the breakdown of organic matter, such as landfill waste, agricultural waste, and wastewater solids, through anaerobic digestion. Raw biogas is a mixture of gases including methane (CH4), carbon dioxide (CO2), hydrogen sulfide (H2S), volatile organic compounds (VOCs), and atmospheric gases like nitrogen (N2) and oxygen (O2). In order to use biogas as a fuel source, either through electricity generation or injection into the fuel grid, it must be purified and the gases separated. Activated carbon is commonly used for these biogas purification and separation processes.

Biogas Applications with Activated Carbon:

Raw biogas undergoes several processing steps to upgrade it to direct combustion fuel or renewable natural gas. Activated carbon can be used in the following biogas upgrading processes:

H2S is typically removed at early stages in biogas upgrading, as it is corrosive and can impact downstream operations. Several different solid medias are used industrially for H2S removal, but GAC possesses both good loading and easier handling/removal characteristics.

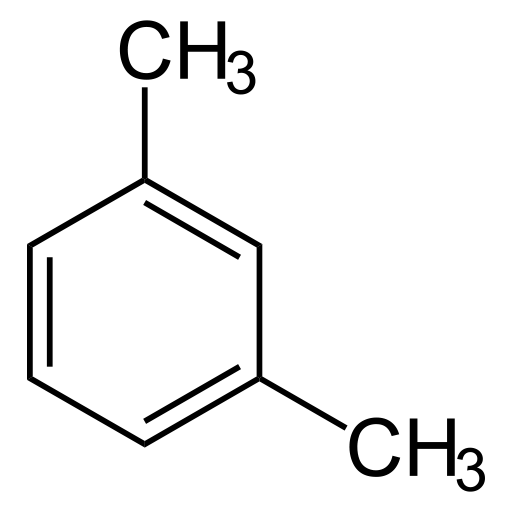

VOCs are present in all types of biogas, but are prevalent in landfill gas (LFG) and some types of agricultural biogas. VOCs are often only removed purposefully in renewable natural gas (RNG) processes due to their impact on downstream processes. VOCs can be removed with activated carbon, and in many cases that carbon can be reactivated as a form of disposal, which recycles the carbon for re-use.

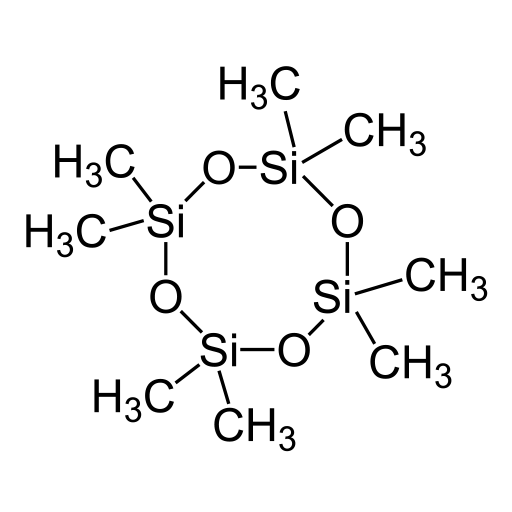

Siloxanes in biogas are volatile organosilicon chemicals that contain a Si-O-Si linkage. When biogas containing siloxanes is combusted, the siloxanes can yield silicon dioxide (SiO2) which deposits into engines and other components and impacts performance, necessitating more frequent maintenance.

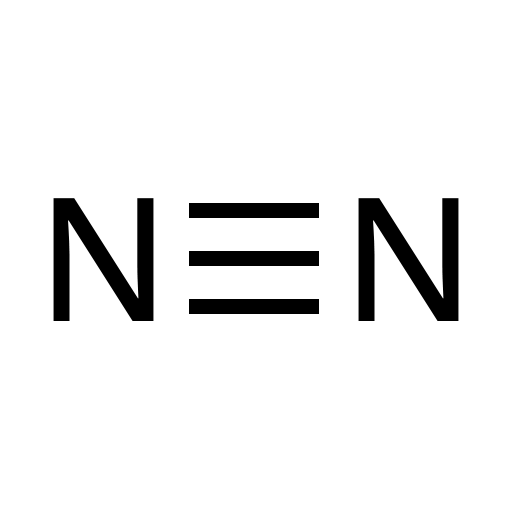

Nitrogen gas (N2) is often present in biogas due to air ingress from the atmosphere, and in some cases N2, and in some cases must be removed to meet pipeline specification for RNG projects. Activated carbon materials are often used in equilibrium PSAs to separate N2 from CH4 prior to pipeline injection by preferentially adsorbing CH4.

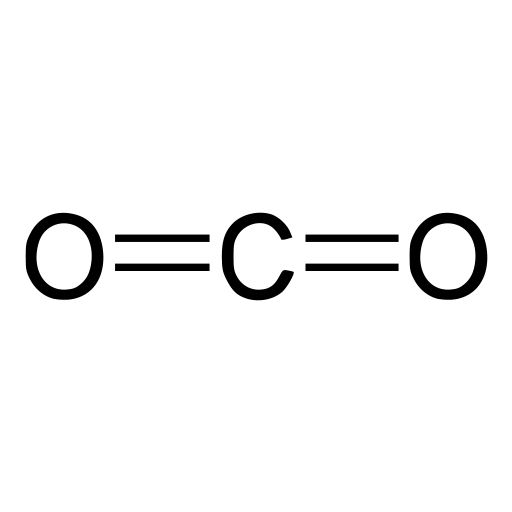

Carbon dioxide gas (CO2) is present in raw biogas in similar concentrations as methane, and in RNG processes the CO2 must be separated. Although activated carbon products tend to have little capacity for CO2 carbon molecular sieves (CMS) used in kinetic mode PSA systems are capable of separating CO2 as well as N2 from biogas.

- Kuraray Carbon Molecular Sieves for biogas separation

Activated carbon is a leading technology for various biogas upgrading processes. Activated carbon is reliable, simple, and has been proven over many years in the industry. It is even possible to substitute activated carbon products into adsorbers designed to use other solid media for applications such as H2S removal.

In addition to the above applications for H2S, VOC, siloxane, and N2 removal, activated carbon products can be used for other specialty applications in biogas including: ammonia removal, mercury removal, compressor or lubricating oil vapors, and others.

Contact Us today and get in touch with your local Sales Representative or Applications Engineer to learn about how our activated carbon materials can be a solution in your planned or operational biogas process.

Activated Carbon

Calgon Carbon has over 70 years experience in manufacturing of the highest quality activated carbons for use in biogas applications. Activated carbon products are available in a range of granular and pelletized or pelleted particle sizes to fit the stringent requirements of industrial applications.

Learn More >>Reactivation Services

Calgon Carbon offers safe and economical spent carbon handling and thermal reactivation (total destruction of the adsorbed organics), including RCRA Hazardous spent carbons, in conjunction with fresh carbon supply and provides personnel and equipment to perform the carbon exchange on a turnkey basis.

Learn More >>Equipment

Calgon Carbon can bundle the performance advantages of vapor phase activated carbon with adsorption equipment (service or purchase) and related services, to provide a full turnkey solution. Ask us about our full-service rental Mobile Adsorbers for biogas applications.

Learn More >>